A forklift is a powerful machine that allows one individual to accurately lift and place large loads with little effort. However, it is essential to avoid an accident in the warehouse and get forklift certified today! Training should always include hands-on experience on the forklift.

We’ve compiled this manual to make sure you have the Ultimate Guide to Forklift Training!

Step 1: Get a Forklift Certification

OSHA standards require forklift training and certification for any employee who operates a powered industrial truck 1910.178(l)(6). Visit Certifyme.net today to get your forklift certification without jumping through any hoops!

While getting a certification is the first step, it is essential to always be conscious of other factors that may affect the safety of yourself and other co-workers.

Step 2: Training Overview

Training reduces the risk of accidents and it’s important to get supervised experience on the forklift before using it. All new powered industrial trucks acquired and used by an employer shall meet the design and construction requirements for powered industrial trucks, but employees need to take precautions as well. 1910.178(a)(2) Employees must utilize common sense and abide by other normal procedures such as checking controls before operating, wearing proper equipment and being conscious of the environment.

There’s no replacement for acknowledging safe practices. Use your best judgment around forklifts and in the warehouse to keep accidents to a minimum.

Step 3: Safety

Safety is always first! Safety inspection is performed once per day or shift. 1910.178(l)(3)(i)(J). Start by inspecting the vehicle to make sure nothing is amiss or broken with the forklift. Immediately notify your supervisor if anything is wrong or feels strange. Check the weight of the load 1910.178(a)(5) by making sure to stay within the forklift’s lifting capacity in order to prevent tipping or breaking the machinery. Remember, a heavier load will quickly drain the electricity on the battery. Additionally, check pallets and remove any loose items 1910.178(n)(14). Make sure all the loads are secure 1910.178(o)(1) before operating the vehicle and driving. Lower your forklift’s loads to drive 1910.178(m)(5)(i)

As an extra safety precaution, cages on a forklift can protect you 1910.178(m)(9) and will prevent any overhead items from falling on you or injuring you. You can also wear a helmet for additional protection.

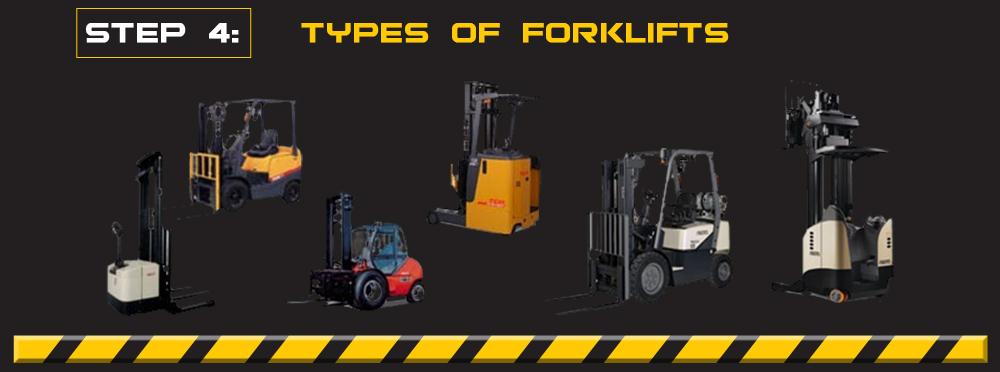

Step 4: Types of Forklifts

There are a variety of forklifts in the industry and its purpose is to always move, carry, pull and push heavy material to a new location. Powered industrial trucks are classified into seven types based on their characteristics.

Class 1: Electric Motor, Rider, Counter-Balanced Trucks (solid and pneumatic tires)

Class 2: Electric Motor Narrow Aisle Trucks (solid tires)

Class 3: Electric Motor Hand Trucks or Hand/Rider Trucks (solid tires)

Class 4: Internal Combustion Engine Trucks (solid tires)

Class 5: Internal Combustion Engine Trucks (pneumatic tires)

Class 6: Electric and Internal Combustion Engine Tractors (solid and pneumatic tires). There are no forklifts in this class.

Class 7: Rough Terrain Forklift Trucks (pneumatic tires)

Step 5: Electric Forklifts vs. Gas Powered Forklifts

There are many pros or cons to driving an electric or gas powered forklift. An electric forklift may need to be frequently charged while a gas forklift has exhaust, which requires plenty of ventilation for indoor warehouses.

An electric forklift must have the braked set before it is charged. 1910.178(g)(8) Additionally, an individual with simply a forklift certification cannot charge the electric forklift. Specialized and trained individuals must charge the forklift. It is important to note that a minimum charge should be 1/2 of capacity or 3/4 for heavy loads. Heavier loads will drain the battery faster. 1910.178(o)(2)

With gas forklift there is always a danger of carbon monoxide poisoning or a fire. Adequate ventilation is needed to disburse fumes. It is essential to always have an extinguisher nearby in the event of a fire.

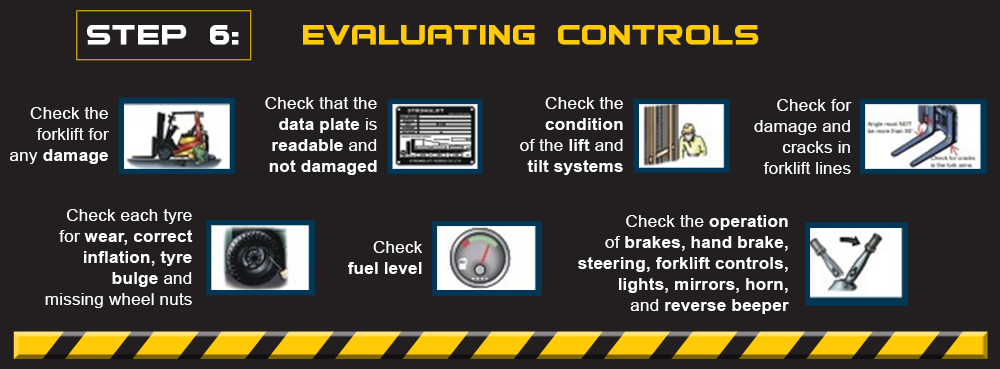

Step 6: Evaluating Controls

When starting up the forklift, go through a mental checklist to make sure the following items are fully functional:

• Is the horn working? 1910.178(n)(4)

• Check the steering mechanism with the engine running. 1910.178(n)(15)• Evaluate the breaks 1910.178(m)(7)• Check the seat brake.

• Is there any lint, grease, or oil where the forklift can catch on fire?

• Check the tires

• Check that the clutch disengages the transmission.

• Check the hydraulic controls-lift and tilt levers before picking up the load

Any issues that would affect safety must be fixed before the forklift is returned to service.

Step 7: Driving a Forklift

Your forklift isn’t the only thing you have to check! The basic rule for traveling is that you maintain control of your forklift at all times.

Make sure that issues beyond the forklift will not affect you such as overheard items or slippery floors. It’s essential to prevent items that the forklift can hit or catch.

• Never drive blind. 1910.178(n)(3)

• Be aware of overhead items. 1910.178(m)(8)

• Never travel with a raised load. 1910.178(n)(7)(iii)

• Make steady accelerations and decelerations.

• Make sure you have the enough space.

• Be aware of obstacles, both ahead and overhead. 1910.178(m)(8)

• Be cautious about cable trays.

• Move materials only in the designated areas with adequate space. 1910.178(l)(3)(ii)(E)

• Do not block individuals into a stack.

• The amount of people in the area

• Never engage in horseplay 1910.178(n)(9)

• Always remove the keys after use

• Be conscious of elevated or descending areas 1910.178(n)(7)

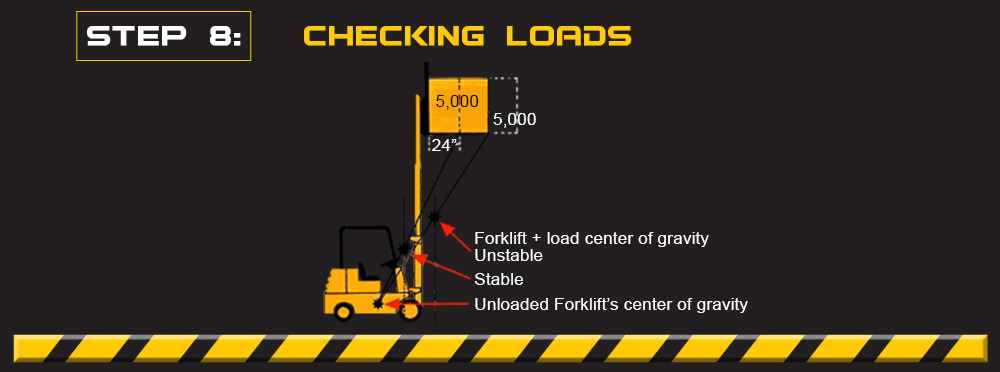

Step 8: Checking Loads

One of the most important aspects of forklift management is checking the load. Most loads are moved on pallets. Reduce the risk of an accident by always centering the load on the fork and not working within a tight space. The load should always be tilted backwards to prevent the items from falling.

• Be cautious of loading areas. 1910.178(m)(7)• Be conscientious of the total capacity. 1910.178(o)(2)

• Do not exceed load center.

• Be aware that fork extenders make the load less stable. 1910.178(o)(1)• Most tipping accidents happen because of the above problems.

Step 9: Setting Down A Load

After the forklift has driven the load to the designated area, the operator needs to set down the load carefully. Drivers must first set the brake and make sure it does not block any entrances or people. After the brake is set, tilt the mast back to the vertical, which will keep the items stable and evenly distribute the load weight when set down. The forklift operator will then slowly lower the load until the pallet is on the floor. Gently lift the forks just to release the pallet and clear the forks by moving backwards. If the load is in a tight location, seek a spotter to help you safely execute this task.

Step 10: Operator Responsibility

The forklift operator is in charge with assuring that all forklift movements are conducted safely. A forklift is a powerful tool when used by a well-trained operator. It is easy to become complacent from routine, but it’s up to you to be on top of it! Don’t make bad decisions you could regret later. It is important for use your best judgment and be safe instead of sorry. If you feel that anything is wrong with the forklift or there is a situation you can’t handle notify your supervisor or employer immediately.

Get trained and earn your certification today!