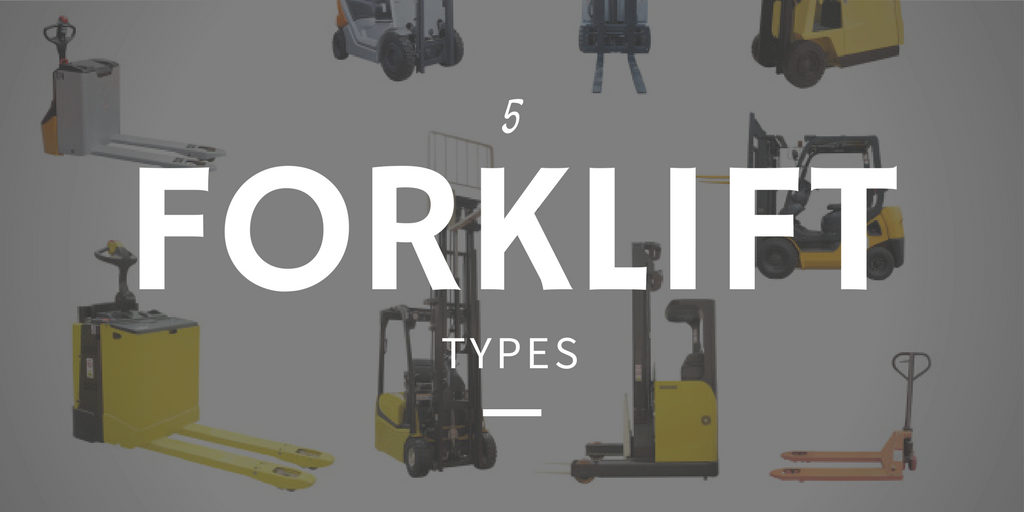

Understanding the Different Forklift Types

Most people understand what forklifts are and the basics of how they’re used. The average person doesn’t typically know about the wide variety of forklift types available for use, though. If you’re unsure about the differences between a rider, powered pallet, or teletruck, you’ve come to the right place. We can walk you through the features, capabilities, and hazards associated with various types of forklifts.

Most people understand what forklifts are and the basics of how they’re used. The average person doesn’t typically know about the wide variety of forklift types available for use, though. If you’re unsure about the differences between a rider, powered pallet, or teletruck, you’ve come to the right place. We can walk you through the features, capabilities, and hazards associated with various types of forklifts.

This overview is an excellent starting place, but if you’re thinking of becoming a forklift operator, you’ll want to continue your education through formal forklift certification training. By understanding the unique features and requirements associated with each different type of forklift, you’ll be ready use these incredible machines to their full capacity.

Understanding Various Forklift Types and Classes

OSHA divides forklifts into seven distinct forklift classifications. These are based on many factors, including:

- Type of engine

- Type of carriage

- Type of forks

- How the forklift is operated

- The type of jobs it is suited for

- Indoor versus outdoor worksites

Knowing the different OSHA forklift classifications can help ensure you use the right truck for the job. Different kinds of forklift classes include:

Class I.

Electric motor rider forklifts.These are best suited for loading and unloading tractor-trailers, handling pallets, and other indoor job tasks. They are often seen in food storage, retail, factory, and general warehousing job sites.

Class II.

Electric motor narrow aisle forklifts.These are also called reach trucks or order pickers. They are designed for easy maneuverability in tight spaces.

Class III.

Electric pallet jacks, stackers, and tow tractors.This class offers rider and walk-behind models. They are good for unloading deliveries and moving loads to a staging area where they can be handled by different types of forklifts.

Class IV.

Internal combustion cushion tire forklifts.Designed for indoor use, this class has IC engines that run on diesel fuel, LP gas, gasoline, or natural gas. Their cushioned tires provide a smooth ride on indoor surfaces, and can’t be punctured.

Class V.

Internal combustion pneumatic tire forklifts.These forklifts are similar to those in Class IV. They tend to be more durable and are used outdoors instead of inside.

Class VI.

Electric/IC engine tow tractors.These are often used for towing loads rather than lifting. They are a popular choice at airports and assembly lines. They can have electric or IC engines.

Class VII. Rough terrain forklifts.These forklift types have large, tractor-style tires for outdoor use in rugged terrain. They are used at lumber yards and construction sites to lift building materials to above-ground work sites.

Eager to learn more about forklift types? Explore our resources for further information.

Basic Forklift Types: Electric vs. Internal Combustion

Forklifts are powered by two types of engines – electric and internal combustion (IC). Each type of engine is suited for different types of work environments and job tasks. This makes the power source a key factor in which forklift style a business will use.

The advantages of electric forklifts are many. They don’t emit harmful emissions. This makes them better suited for cramped areas with poor ventilation. Electrics are quieter than IC engines. They also require less maintenance. On the downside, electric forklift types cost more to buy than IC models. However, they tend to have fewer repairs. This extends their service life, making them more cost-effective over the long run. When the battery runs down, it can take a long time to recharge. This means downtime for the truck unless the company invests in extra batteries.

IC forklift types can run on gasoline, diesel or propane. Their engines are more powerful than electrics and can lift heavier loads. They are built to withstand rugged work conditions, whether inside or outside. IC trucks are also well suited for multi-shift operations because they can be quickly refueled. Their maintenance costs tend to run higher. They also release harmful emissions, which requires a good ventilation system when used indoors.

Five Different Kinds of Forklifts

Now that we’ve covered the different classes and explored the differences in engine types, let’s look at different kinds of forklifts:

1. High-Lift Truck

This forklift type is a heavy-duty workhorse. High-lift trucks are powered by gas or diesel, and are designed to raise loads to upper heights. This makes it ideal for lifting and moving heavy items in a variety of job sites. Airlines often use them to repair and clean aircraft. Warehouses with high racking use them to maximize the vertical space. Because of the high lifting, load limits should never be exceeded. For safety, these trucks should be kept away from the edge of loading bays or ramps.

2. Low-Lift Truck

These forklift types are not designed to lift and place materials on high shelves. Instead, they are used to raise loads just enough to permit horizontal movement. Powered by an electric engine, low-lift trucks should always have the load face uphill. They should also drive in reverse when going down ramps.

3. Rough Terrain Forklift (RTFL) Trucks

There are two different types of forklift trucks in this group: straight-mast and extended-reach. RTFLs are very mobile, and are often used in docks, timber yards, construction sites and other rough areas. Powered by diesel, RTFLs provide a safe way to travel with loads on uneven ground.

4. Straddle Truck

These forklifts are used for moving and stacking ISO standard containers for the shipping industry. They can lift up to 60 tons at low speeds. This is the same as two full containers. Straddle trucks can stack containers more than 13 ft. high. Drivers sit at the top of the truck so they can see in front and behind them. These trucks also come in mini versions to move containers around yards and depots.

5. Cantilever Trucks

These forklifts are used to handle lumber, steel bars, pipes, and other long products. Unlike other forklifts, they don’t have front uprights that can get in the way of loading and unloading. Also, they aren’t driven like other different kinds of forklifts. They are installed onto trucks to improve the loading and unloading process.

Types of Forklift Suspensions

Most forklifts have a three-point suspension system that consists of two front wheels and a pivot point at the rear axle. Together, these points create a “stability triangle” that minimizes the risk that a lift will tip over, even on steep or rugged terrain.

Thanks to the stability triangle, a forklift remains level, due to the fact that its center of gravity falls within this triangle. If the lift is moving forward or backward or parked on a slope, its center of gravity shifts. In this instance, the forklift’s center of gravity falls outside the stability triangle. The result: the lift will tip over.

A forklift’s center of gravity moves any time a lift operator accelerates, brakes, or turns. Thus, a lift operator must account for the lift’s center of gravity at all times — because failure to do so could result in a tip-over. Different types of forklifts come with unique challenges and hazards, which is why it’s so important to be knowledgeable before you begin using them.

Which Type of Forklift is Right for You?

As you can see, the wide range of forklift types can make it challenging to know which is right for the task at hand. If you’re considering investing in a lift for your business, be sure to consider the following factors before buying:

Key factors to consider as you assess different types of forklifts include:

- Capacity: Ensure a forklift’s maximum lifting capacity meets your business requirements

- Weight: Verify that the ground at your jobsite can handle a forklift’s weight

- Height: Assess the forklift’s height to ensure the lift can safely pass through openings across your worksite

- Fuel Type: Determine if a forklift will be used primarily indoors or outdoors; an electric lift may be a better choice indoors due to its low emissions, while a lift with an internal combustion engine offers a high carrying capacity that can make it a great option for outdoor applications

- Terrain: Find out if a forklift will be used primarily on smooth or rough terrain; a three-wheel lift is generally ideal for indoor use, while a four-wheel lift can help you safely move heavy loads on steep or level surfaces.

Learn as much as you can about the different types of forklifts, and you can make an informed decision regarding which lift is best for your company.

OSHA Requirements for Forklift Training

Understanding what are the different types of forklifts is just the beginning. Before you can operate any forklift, you must be properly trained to do so. This isn’t just a recommendation: it’s the law. Employers are required to provide OSHA-approved training to their workers at no cost. This training process should encompass all different forklift types used in your organization. After completing the written instruction, hands-on training, and a skills assessment, workers will earn their certification and become licensed to operate forklifts.

Of course, this license doesn’t last forever. OSHA requires workers to recertify every three years. Recertification is also necessary following a forklift accident, unsafe driving behaviors, or when working conditions change, including the use of a new type of forklift.

Earn Your Forklift Certification Today

Forklift types vary – there’s a lot to learn about them. Nothing is more important than knowing how to safely operate them, though. ForkliftCertification.com offers convenient, affordable, OSHA-certified training that’s designed to keep your workers safe. We can train your employees on the forklift types they need to perform their duties as efficiently and safely as possible. To learn more, reach out to our team online or give us a call at (888) 278-8896.